Rack And Pinion Actuator Manufacturers

The rack and pinion driven modular actuator come with an internal linear ball bearings that can be adjusted free of play is driven along the guide rods by a high precision rack.

Rack and pinion actuator manufacturers. This rotary action is achieved through the use of double integral pistons and racks that drive the connecting pinion. Rack and pinion actuators form part of the linear actuation range that converts linear motion to rotary which enables the on off and application control of quarter turn ball butterfly and ball valves. Valve interfaces generally comply to the iso 5211 standard. Available as double acting or spring return with torque outputs for small to large valves.

Both actuators have twin cylinders horizontally opposed incorporated piston guides to assure the correct contact between the rack. Our company is a well known manufacturer and a supplier of an excellent range of rack pinion aluminum actuators which are made using a high quality of raw materials in the market. These products are available at very. The top supplying country or region is china which supply 100 of rack and pinion actuator respectively.

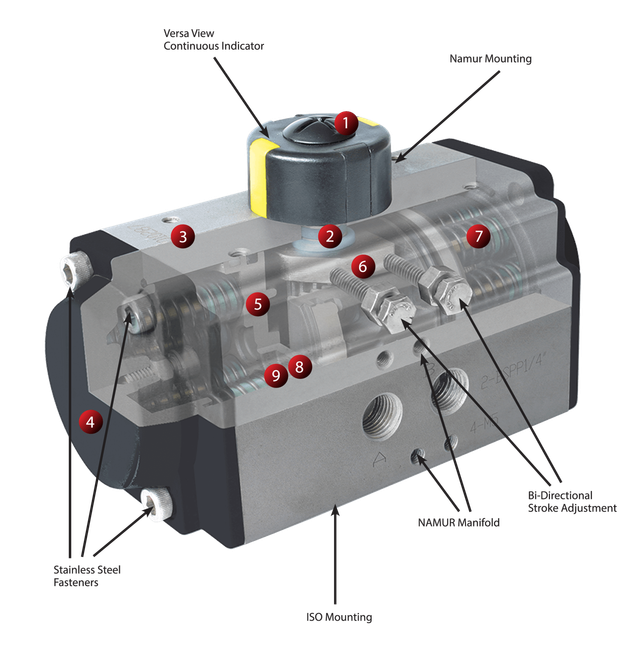

These standards specify dimensions for various components such as actuator to valve interface air ports position indicator interface and shaft driver shapes. The torquemate pneumatic rack and pinion actuator is one of the best designs in the market. To be compatible and interchangeable with the products of various manufacturers most pneumatic rack and pinion actuators have been standardized. About 53 of these are pneumatic parts 6 are rack gears and 6 are dc motor.

This torque based standard has become the industry standard and many valves are available that allow direct mounting eliminating cost for bracket and coupling. Our products have an excellent design and they are made using the best available technology in the market. Rack and pinion actuators have standardized interface flanges interfaces for valves solenoids and control accessories. The rack and pinion system is suitable for highly dynamic.

We also cover the operating conditions and mounting standards that our expert rack and pinion actuator manufacturers recommend. They can be seen in figure 6.