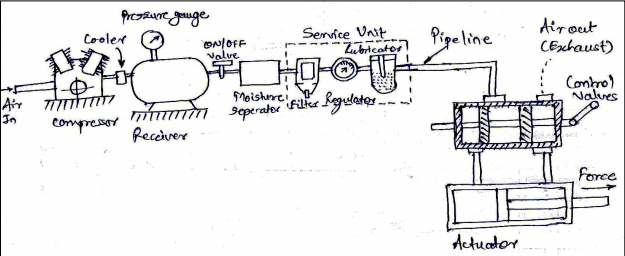

Pneumatic Actuation System Layout

In general pneumatic systems are used for gripping and or moving operations in various industries.

Pneumatic actuation system layout. Piston type fluid accumulator general design. Pneumatic actuators come in many designs and sizes and include a variety of mounting methods internal features and options to provide a robust solution in industrial environments table 2. For instance there are thousands of types sizes and variations of cylinders and valves from off the shelf versions to custom designs. However when a large amount of force is required to operate a valve for example the main steam system valves hydraulic actuators are normally used.

Quarter turn rotary actuators. It operates by a combination of force created by air and spring force. Diaphragm cylinders rodless cylinders telescoping cylinders through rod cylinders etc. In order to get a better overview we position the air preparation on the bottom and the actuators on the top of the drawing.

There are many styles of pneumatic actuators. A simplified pneumatic actuator diagram of a pneumatic actuator is shown in figure f1. A rubber diaphragm separates the actuator housing into two air chambers. Understanding pneumatics is a matter of physics.

It s reliable economical and surprisingly easy to use. Actuators are output devices which convert energy from compressed air into the required type of action or motion. The sketch exemplifies a pneumatic system at the machine level. It operates by a combination of force created by air and spring force.

A simplified diagram of a pneumatic actuator is shown in figure 1. They are ideal for quick opening and closing in both on off and control applications. Pneumatic actuator design and operation. Hydraulic actuator design and operation pneumatic actuators are normally used to control processes requiring quick and accurate response as they do not require a large amount of motive force.

Pneumatic actuation plays a major role in today s world of computerized automation. They display the route of the compressed air. Pneumatic system design considerations. Pneumatic systems as a whole can be simple but this simplicity can be deceptive when it comes to selecting components.

The actuator positions a control valve by transmitting its motion through the stem. Pneumatic actuators are the most commonly used valve automation systems. Air cylinders and motors are the actuators which are used to obtain the required movements of mechanical elements of pneumatic system. A safe pneumatic system design starts at the connection to a machine s air preparation hardware and continues to correctly pairing valves with cylinders.