Plastic Extrusion Die Design Software

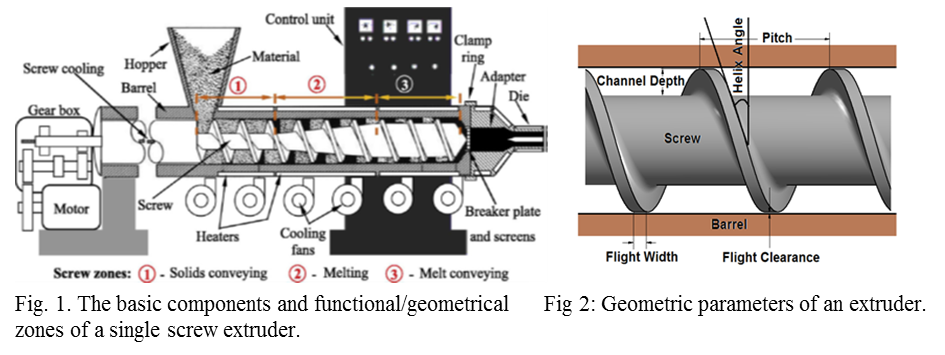

In die design problems often occur because the product designer has little or no appreciation for the impact of product design details on the ease or difficulty of extrusion.

Plastic extrusion die design software. Plastic flow s extrusion die design software polyxtrue is based upon a unique and proprietary theory that simulates flow of polymers taking into account not only the shear viscosity but also the elongational viscosity of the polymer. We design and build tooling for all those processes but to date we have only been involved in extrusion dies for symmetrical profiles. The polyxtrue software has been successfully used to design new monoextrusion dies as well as to optimize existing dies. Qform extrusion integrates all the features required for analysis and optimization of the most complicated extrusion processes.

The extruded material can be aluminum alloys magnesium brass steel and other metals. Using the computer simulation of the flow in extrusion dies with polyxtrue you can develop the die channel geometry such that a uniform velocity distribution is obtained at the exit die balancing and the pressure drop in the die is minimized. This system helps create the solid model of a tooling set step by step using special parametric design tools. Side fed die cross head die design for pipes cables or blow molding extrusion.

Extrusion die design qform extrusion die designer qexdd is an automated system for 3d design of dies mandrels and other parts of the tooling set for extrusion of aluminum hollow and solid profiles. Flat die design for sheet extrusion and extrusion coating. Profile die design for plastics and rubbers. What is altair inspire extrude polymer.

Plastic extrusion die design software recommendations hi everyone we are a toolmaking operation in a group of companies involved in metal pressing injection molding blow molding and plastic extrusion. Spiral die design for tubular film pipe extrusion and blow molding heads. In many cases small design changes can drastically improve or degrade the extrudability of the product. Flat spiral die design for coextruded blown films.

To simulate a multilayer flow during coextrusion polyxtrue uses a newly developed algorithm called mesh.